Medical waste disposal’s impact on disease transmission and the environment continues to be a growing concern in today’s society. Therefore, it is very important to properly handle them. As one of the professional manufacturers of carbonization equipment for waste medical, we promise that our medical waste carbonizing plant adopts highly advanced technology and has the features of saving energy 30%, protecting the environment and ensuring safety 100%. There are some types of medical waste carbonizing machines, different models have different capacities, but they have the same working process as follows:

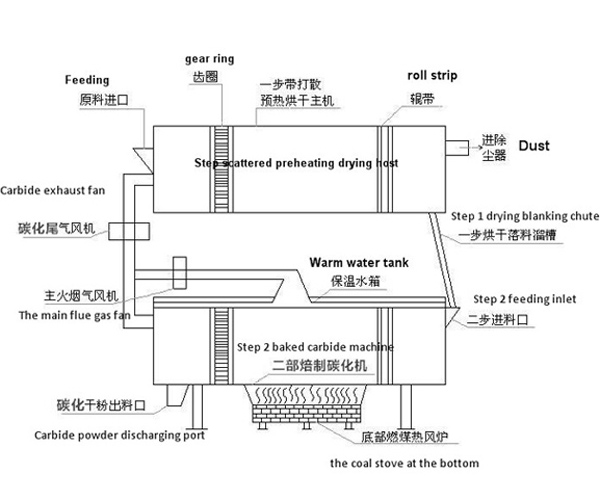

1.Use the material reclaimer unit to collect the medical waste into the Measuring Conveyor.

1.Use the material reclaimer unit to collect the medical waste into the Measuring Conveyor.

2.The dispersion foggy device in the timber dryer pre- dries out the medical waste and the waste medical freely falls inside the carbonization unit and be dried out for the second time.

3.Then the medical waste falls in the outside bin of the system and starts the high temperature pyrolysis, sulfur emission, flue gas volatile, carbon focused carbide process.

4.The carbide will be discharged by the water-cool conveyor, and the rest hot flue gas and heat will be suffered desulfurization process and smoke abatement process.

5.The smoke abatement and desulfurization steam will be cooled by the condenser and led to the recycle water pool.

The features of medical waste carbonization system:

The features of medical waste carbonization system:

1.The heating is used fully in the whole process of operation, so the heat use ratio of our machine is over 85% under the inspection of related institutes;

2.Our machine can be designed according to customers’ local cheap fuel, so our clients can save cost and achieve the virtuous circle at the same time;

3.It only uses one hot air source in the whole process, therefore, the production cost in the whole process is lower;

4.The by-product is artificial carbon, which owns fixed higher carbon content (about 90%). Compared with the general coal, its carbon content is twice as much as that of the general carbon.

| Item | Details | |||

| Model | BST-05 | BST-10 | BST-20 | BST-30 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous | |||

| Raw Materials | 1.All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. 2.Civil sludge, municipal sludge, industrial sludge, etc. 3.Municipal solid waste. |

|||

| Reactor Size | Φ800 | Φ1000 | Φ1300 | Φ1700 |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Diesel, Natural Gas, LPG, Biomass, etc. | |||

| Total Power | 40 kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life span | 5-8 Years | |||

License photos: