The biomass carbonization machines for making briquettes are widely used. The biomass briquettes are made from the sawdust and other agriculture residues such as crop straws, rice husks, bamboo shavings, and grasses . The biomass carbonization machine for making briquettes adopts one fire two step method, which is unique in the world. So far there is no other technology equipment could be mentioned with us in the same breath.

Meanwhile, our biomass carbonization machine for making briquettes boasts double-layer design, which will make the lower part of the machine contact the hot air as much as possible, so this design is helpful to raise the heat utilization efficiency from the beginning. There are three times to make maximum full use of the heat in the whole process of operation, so the temperature of the emission gas is below 100 centigrade and the heat use ratio of our equipment is over 85%. What’s more, there is only one hot air source used in the whole process of operation, and the whole equipment is equipped with a treatment technology that is used to deal with the left heat and smoke after being pre-dried.

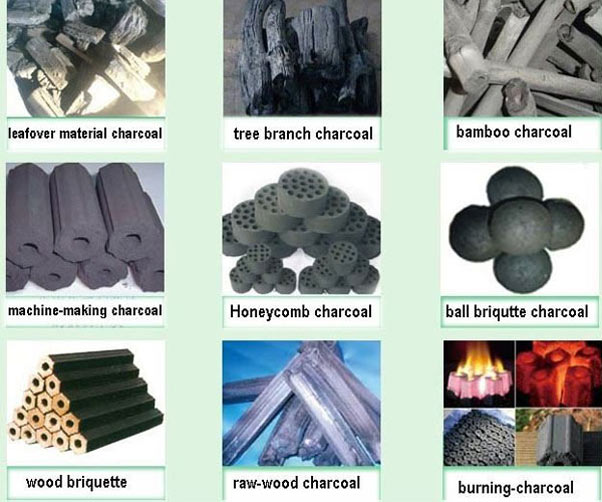

The Use of the End Product :

1. Agriculture: It can be used to improve the soil quality and heat the green house.

2. Industry: It can not only be reprocessed into active carbon, but can also be used for construction bricks with clay, what’s more, it can be applied to the generator to get the electricity.

3. Daily Life: It can be used as fuel in BBQ and other areas.

After-Sale Service about Us:

1. For each set of carbonization furnace machine, one technician will be sent to guide your installation, test the machine and train your workers.

2. Based on our customers’ site and budget, our experts will design efficient, reliable installation drawings

3. 1 year warranty, engineers available to service at any time

4. Periodical call visit, to make sure there is no problems of the equipment

| Item | Details | |||

| Model | BST-05 | BST-10 | BST-20 | BST-30 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous | |||

| Raw Materials | 1.All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. 2.Civil sludge, municipal sludge, industrial sludge, etc. 3.Municipal solid waste. |

|||

| Reactor Size | Φ800 | Φ1000 | Φ1300 | Φ1700 |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Diesel, Natural Gas, LPG, Biomass, etc. | |||

| Total Power | 40 kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life span | 5-8 Years | |||

License photo: